The key factor to the superior insulation capabilities of our XPS foam boards is the 100% virgin polystyrene material we incorporate into our product.

To ensure a strong comprehensive strength and chemical stability, we only use virgin polystyrene materials instead of recycled ones. Our use of pure polystyrene on our boards ensures we satisfy every business requirement.

Ourgreen is capable of manufacturing machines that produce high-quality XPS foam boards, setting us apart from other insulation solution providers.

The Mettler Toledo dosing scales we utilized ensure accurate input and homogeneous mixing of raw materials to prevent fluctuations during production.

We use TRICOR mass flow meters to maintain accurate CO2 gas control and measurement throughout the extruded polystyrene foam board manufacturing process.

We can lower the structural density of our XPS foam board with our large screw extruder, providing you with a flexible solution for specific applications.

The incorporation of our Multi-Roller Haul-off Machine ensures more stable manufacturing process and flat surfaces on all of our XPS foam boards.

Ourgreen XPS foam boards are produced by Eco-friendly CO2 foaming technology, which has no harm to the ozone layer.

The tech ensures all of our boards to have incredibly strong compressive strength yet with low density. We are capable of manufacturing a CO2 injection system that lets you create your line of insulation solutions that meet market demands.

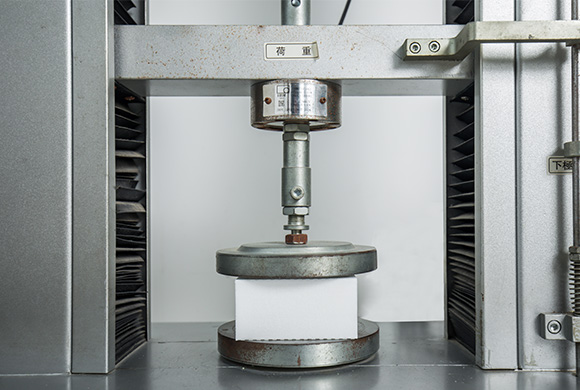

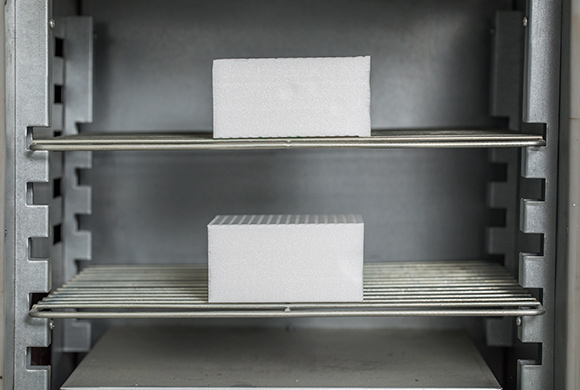

As a reliable XPS foam board manufacturer, we run our XPS foam boards through several tests to meet your expectations.

The test involves applying force onto our XPS foam board through our Compression Tester. We can determine whether our insulation material meets the shock and impact resistance requirement in XPS industry standard.

The test process requires us to ignite XPS Board and measure how much oxygen is needed to judge whether it complies with order requirements of B1/B2 Grade. For B2 Grade, Oxygen Index equals to 26 while for B1 Grade it is 30.

We put two pieces of XPS foam boards into a special chamber, set different temperatures to the cold side and the hot side to get the specific thermal conductivity value. The test ensures each of our XPS boards can achieve the proper insulation solution for various applications.

Through our dimensional stability tester, we can measure the dimensional deformation rate of our XPS insulation board following the national standard requirements.

Below is a collection of reports and certificates, showing the superior insulation properties of our boards.

Copyright © 2020, Ourgreen. All rights reserved.